Transforming packaging for nicotine pouches, one innovation at a time.

With a passion for quality and a commitment to innovation, we're crafting safe and professional plastic packaging solutions that support the global effort to reduce smoking rates and promote harm reduction.

OUR APPROACH

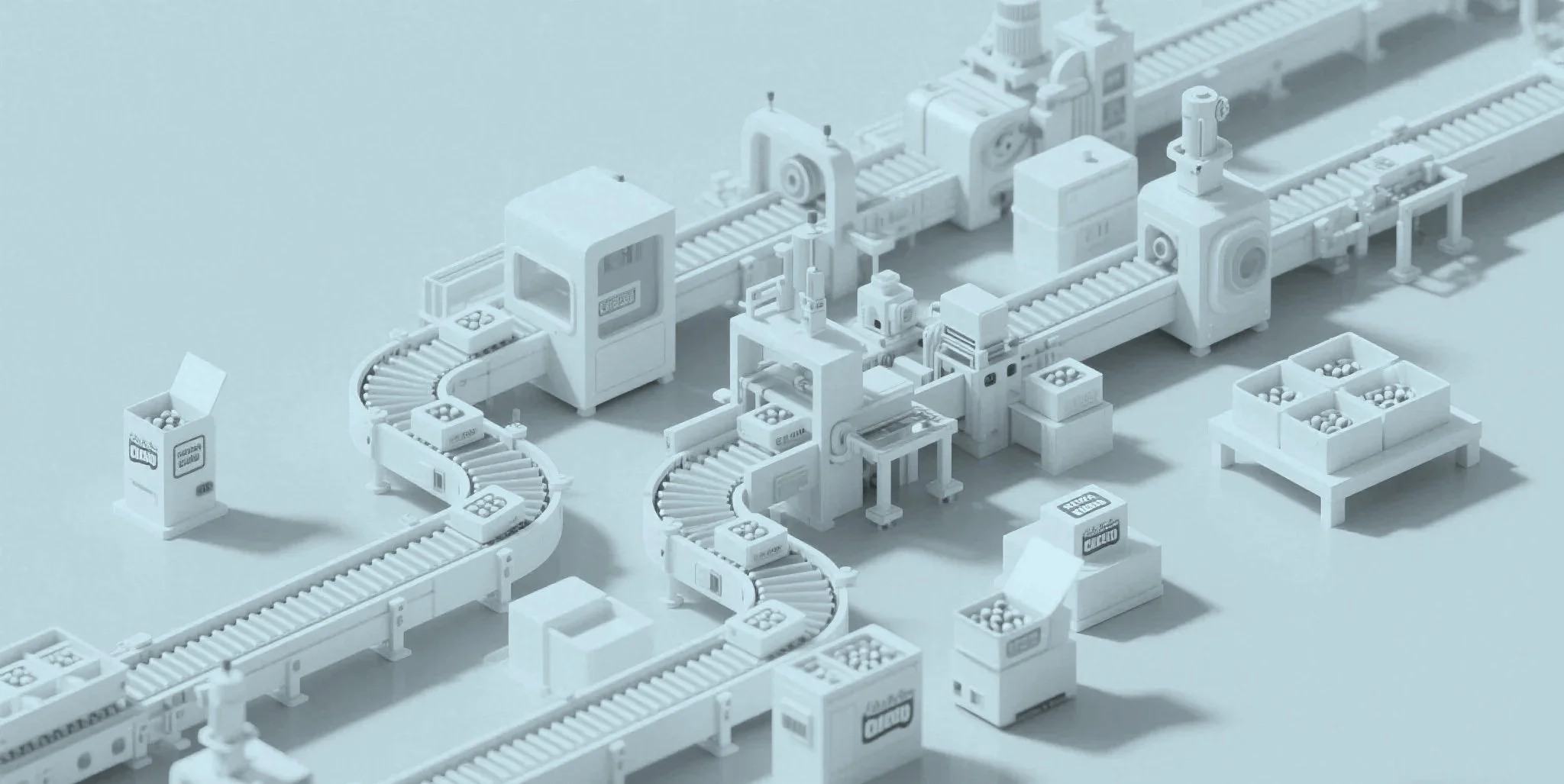

We see packaging not just as a vessel, but as a canvas for progress and possibility. Guided by a commitment to innovation, precision, and reliability, our purpose-built facility is dedicated exclusively to the production and science of plastic containers for snus and nicotine pouches.

Collaboration is at the core of our process. By working closely with leading manufacturers of nicotine pouch packaging machinery, we ensure seamless integration and peak performance on the production line. Each detail, from authentication features to the tactile smoothness of the lid, is honed to elevate both function and form.

With a maximum annual capacity of hundreds of millions cans and an official launch set for June 2025, we are poised to redefine what is possible in nicotine pouch packaging.

Within these walls, advanced technology and modern design converge. Our environment is meticulously controlled—dust-free and optimized for high-volume production—ensuring every can meets uncompromising standards of quality and consistency. The result is a range of containers that reflect both diversity and distinction, from classic forms to bespoke creations shaped by your unique vision.

In Sweden, they call it a “dosa” - for us, it’s a symbol of innovation, partnership, and the future of harm reduction.

Putting a Stop to the Counterfeit Market.

In the fight against counterfeiting, we're leveraging cutting-edge technology to safeguard the integrity of our products. Our advanced diamond cutting CNC technology empowers us to engrave logos and authorizations with unparalleled precision at the microscopic level, significantly reducing the possibility of successful copying.

This intricate marking process creates a unique "fingerprint" on each plastic can, making replication incredibly challenging for counterfeiters. This level of detail not only serves as a visible mark of authenticity but also as a deterrent, ensuring that our customers receive genuine, high-quality nicotine pouch containers.

By implementing these advanced security measures, we are committed to protecting our brand, and more importantly, ensuring consumer trust in the authenticity of our products.

*Graph is for referrence only.

In-house Tooling

With decades of expertise in precision tooling, our factory stands at the forefront of mold design and manufacturing. We are authorized to utilize leading industrial software solutions, including CATIA, Moldex3D, and CAM, enabling us to deliver highly accurate and efficient design-to-production workflows. Our capabilities extend beyond mold fabrication—we are equipped with a range of ultra-precise mold testing equipment, ensuring every mold meets the most rigorous performance and quality standards. This combination of experience, advanced software integration, and state-of-the-art testing infrastructure positions us as a trusted partner for high-end tooling solutions across diverse industries.

Quality & Capacity

This site is built for high-volume, high-quality production, targeting hundreds of millions sets annually.

Advanced automation ensures precision, consistency, and minimal human contact, with strict hygiene standards upheld throughout. Our scalable, fully automated facility is designed to meet global demand while maintaining top-tier quality and efficiency.

-

Olof Thorelli

Co-Founder and CEO

-

Sean Zhang

Co-Founder and CPO

-

Aron Myhre Nordin

VP